Posted by Carla Pyle, NUA Board Member and Natural Upholstery educator & consultant. Thanks to the folks at Chemical Insights for writing this guest post and providing images.

Last year we shared the exciting news that Chemical Insights convened a national Furniture Flammability and Human Health Taskforce to provide science-based facts about safe & healthy furniture.

Since then, the group has been busy compiling scientific resources and summarizing key facts and action steps that were ultimately compiled in UL Guidance Document 118F: Managing Fire and Chemical Exposure Risks of Residential Upholstered Furniture. To help put this knowledge into practice, Chemical Insights created an educational tool for interior designers: Specifying Residential Upholstered Furniture to Safeguard Human Health and Well-Being: A Toolkit for Reducing Fire and Chemical Risks.

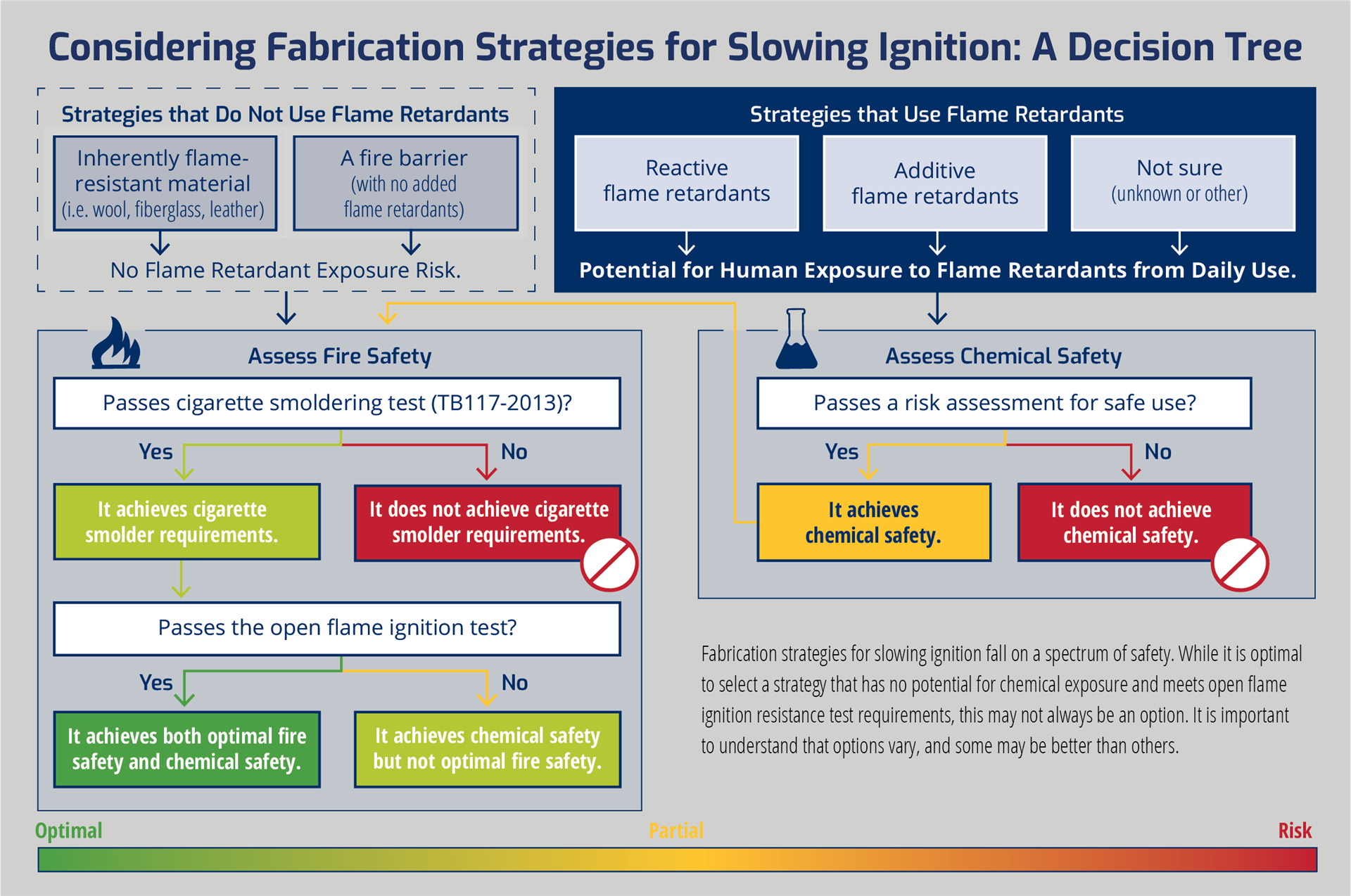

image credit: Chemical Insights

The toolkit:

- Presents a case for why both chemical safety and fire safety must be considered when selecting furniture

- Offers guidance on how to specify solutions that address this safety convergence

- Summarizes meaningful research on flame retardant exposure and furniture flammability.

“There is an abundance of research and information available to designers that addresses mitigating the impacts of consumer products and building materials on indoor air quality. They often focus on six specific classes of chemicals of concern. These chemicals can be released into the air and dust for human exposure contributing to health concerns, especially for vulnerable populations.”

image credit: Chemical Insights

“Current statistics report that of fires that result in death, residential upholstered furniture is the leading item to ignite, above mattresses and flammable liquids. When residential upholstered furniture was the first item to catch on fire, it resulted in 17% of home fire deaths. This suggests that efforts to mitigate residential fire risks associated with upholstered furniture over the past few decades have not been overly successful.”

image credit: Chemical Insights

“Open flame testing showed that a chair with a fire barrier material installed to fully encapsulate the polyurethane foam under the cover fabric (no flame retardants were added) demonstrated significantly lower fire hazards when compared to the other chairs with and without flame retardants (and without barriers).”

WHAT IS A FIRE BARRIER AND HOW DOES IT WORK?

“A fire barrier is a protective layer designed to prevent or delay ignition of the cushioning material. It successfully reduces the fire growth rate and fire size after ignition. Fire barriers can be made from a variety of inherently flame-resistant fibers, including carbons, polyesters and fiberglass.

A barrier should be identified for furniture construction that will delay or reduce open flames.

A fire barrier is installed over the padding or filling materials to completely encapsulate it. In studies, fire barriers have been identified as an effective solution to reduce fire risks without the use of chemical flame retardants — achieving the desired safety convergence. Barriers demonstrate a significant decrease in heat release rate and ignition propensity that results in lower transmitted fire hazards, such as temperature, smoke and carbon monoxide.”

“Just as identifying materials with recycled content or selecting low-VOC paint were once new concepts, specifying a fire barrier in residential upholstered furniture may be a new process for any or all involved parties — the designer, the client and/or the manufacturer. As with all emerging technologies, utilizing a fire barrier may not be an option on all projects and certainly not on all pieces of upholstered furniture — at least initially. However, you are likely to encounter certain situations that make any additional effort and potential cost worthwhile to the client. And as awareness of and demand for solutions that minimize fire hazards and chemical exposure risks grows, just as with the mattress industry, furniture manufacturers are likely to follow suit. There are already manufacturers in the market using the barrier, upon client request.”

image credit: Chemical Insights

LEARN MORE

To view the complete toolkit, alongside additional tools and resources, visit chemicalinsights.org/FFHH.

The National Upholstery Association is proud to present various viewpoints of our members and partners within the upholstery community. Perspectives (or opinions) will vary. This Blog is made available for general information; not to provide specific business, financial, or legal advice.